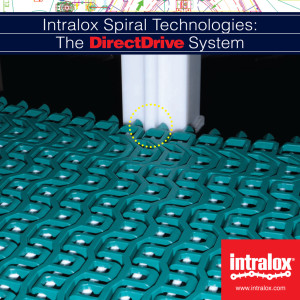

Intralox® DirectDrive Systems

Coastline Equipment designs, builds, and commissions Intralox DirectDrive Systems that increase throughput and product load capacity, while also providing simplified operation, high sanitation construction, and a significant reduction in tension.

OVERVIEW

Intralox Spiral Technology

The Intralox® DirectDrive System advances spiral conveyance technology by eliminating the most common issues related to product migration, tensioning, and sanitation. The patented DirectDrive system uses a dual-diameter operating system that eliminates slip by engaging the conveyor belt edge directly with the drum. The result is a significant reduction in tension, simplified operation, and smoother product handling that eliminates the risk of distorted, damaged or lost product. Intralox technology is ideal for applications where product orientation, belt life, sanitation, and grease/oil buildup are concerns.

Key Benefits

- Reduces product orientation issues such as skewing, distortion, and misalignment.

- Improved cleaning and sanitation results

- Eliminates slip and significantly reduces tension

- Extended belt life: Virtually eliminates inner edge wear

- Eliminates the need for complicated operating controls and primary motors.

- Delays and lags during startup are eliminated, as is the need for friction inserts.

- Increases throughput and has greater load capacity

Request More Information

Over 45 years of experience providing high-quality food processing equipment.

Providing high-quality equipment to Food Processors across the globe.

Design, build, & install equipment across every point on the production line.

Recent News

our services

- Application Analysis

- Project Specifications & Layouts

- Design & Engineering

- Fabrication & Assembly

- Factory Testing

- Installation & Commissioning

- Parts & Service

Contact Us

(360) 734-8509

2235 East Bakerview Rd Bellingham, WA 98226